We recently challenged our team with a number of sophisticated, organic 3D models to print and further optimize our default slicing profiles in regard to break-away support performance. Since well working support structures can be considered the holy grail of the Fused Filament Fabrication (FFF) 3D printing, improvements in this field are on top of our development roadmap.

Being able to fabricate models that extensively rely on support material due to round and organic bottom surfaces or low angle overhangs is crucial for all scopes of application where parts cannot explicitly be optimized for additive manufacturing.

Break-away support structures are geometries or patterns printed in addition to the workpiece, that can later be manually removed from the printed object and are only generated for the purpose of supporting certain geometries of the model during the print. The extra material is printed in a way, so that two objectives are taken into account: To adhere to the printed part to support it where necessary while beeing easily removed during post-processing. As a result the support structures are generated to just barely touch the model surface.

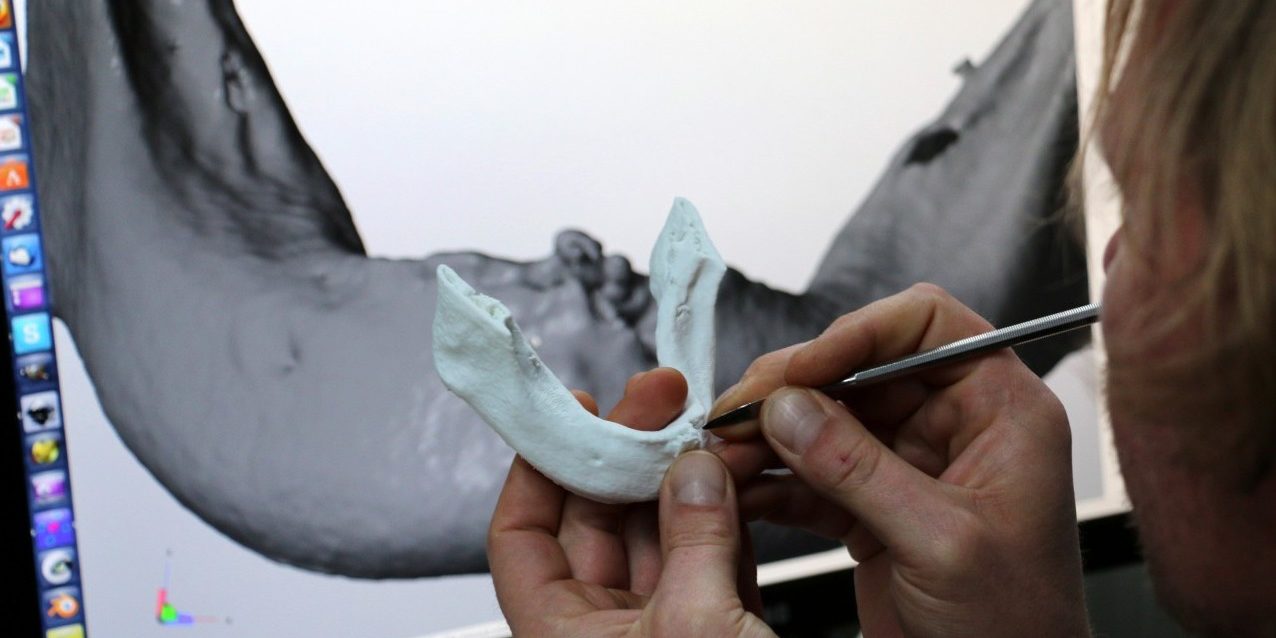

- Jaw Bone

- Printed in 1:1 Size

- Support Structures (back)

- Support Structures (back)

There are materials available to use in the Kühling&Kühling RepRap Industrial 3D printer that are quite easy to print with. The commonly used PLA plastic falls into this category, as well as the relatively new ColorFabb_XT by dutch filament manufacturer ColorFabb – to name just two. Both are characterized by extremely low warping and shrinkage during cooldown in the 3D printing process. Extruded material stays where it is layed down and where it is meant to be, so it is no witchcraft involved in getting the desired results.

ABS plastic is a very different animal in this regard. While having some outstanding mechanical and thermal properties, it is elastically viscous when molten and tends to warp a lot during cooldown. Without optimal slicing parameters, these properties often result in missing contact between the printed model and its support geometries – leading to bad surface finish on the printed part.

ABS is the stuff our RepRap Industrial 3D Printer is primarily designed for, so we pushed our lab printers through their paces with intricate printjobs like this jaw bone CT scan from a dental background and tweaked slicing parameters along the way. As a result, we found one most important parameter for Slic3r, the slicing package we use and recommend, to significantly improve support printing capabilities with ABS material: The bridge speed setting.

As a short background excurse, bridging is the way a filament extrusion 3D printer spans a molten strand of plastic from one pillar to another through the air (like a bridge, hence the name) – the only type of overhang geometry this technology can fabricate without support from beneath. For bridging areas the slicing algorithms need to calculate the flow rate of the filament differently than for regions where material is layed down on top of already printed layers. And Slic3r is also using the exact same parameters to lay down the first layer of the printed model on top of support structures in order to avoid firmly squirting the model material onto the support – to aid for easy removal later on.

So after massively decreasing the bridge speed settings, the surface quality of supported parts and the printing of supported geometries in general could be improved up to the results you see on the jaw bone. That’s what you can expect from break-away support with ABS plastic!

- Supported Bottom Surface

- Removed Support Material

Accordingly we updated our Slic3r configuration bundles on github, compatible with RepRap Industrial hardware revision v1.1.0 and Slic3r v1.1.7-stable.

RepRap Industrial Slic3r profile bundle v03

A huge software and firmware update for previous hardware revision v1.0.0 is underway to make those printers compatible with our latest Slic3r profiles as well very soon.

Ein Kommentar