Remember the diligently promoted jaw-dropping advantages of 3D printing? The promise of beeing able to literally print anything, at least any shape and geometry that may even be unthinkable with common means of manufacturing?

Sure it’s all mathematically provable if you don’t mind diggin’ into Fubini’s theorem for verification, but still there’s this ubiquitous gap between theory and real life. For FFF 3D printing almost the full responsibility weighs on support material being the critical factor for true universal printability. Especially the rapidly emerging market of Open Source FFF 3D printing systems has still been in its infancy in terms of support generation and discrete support materials so far.

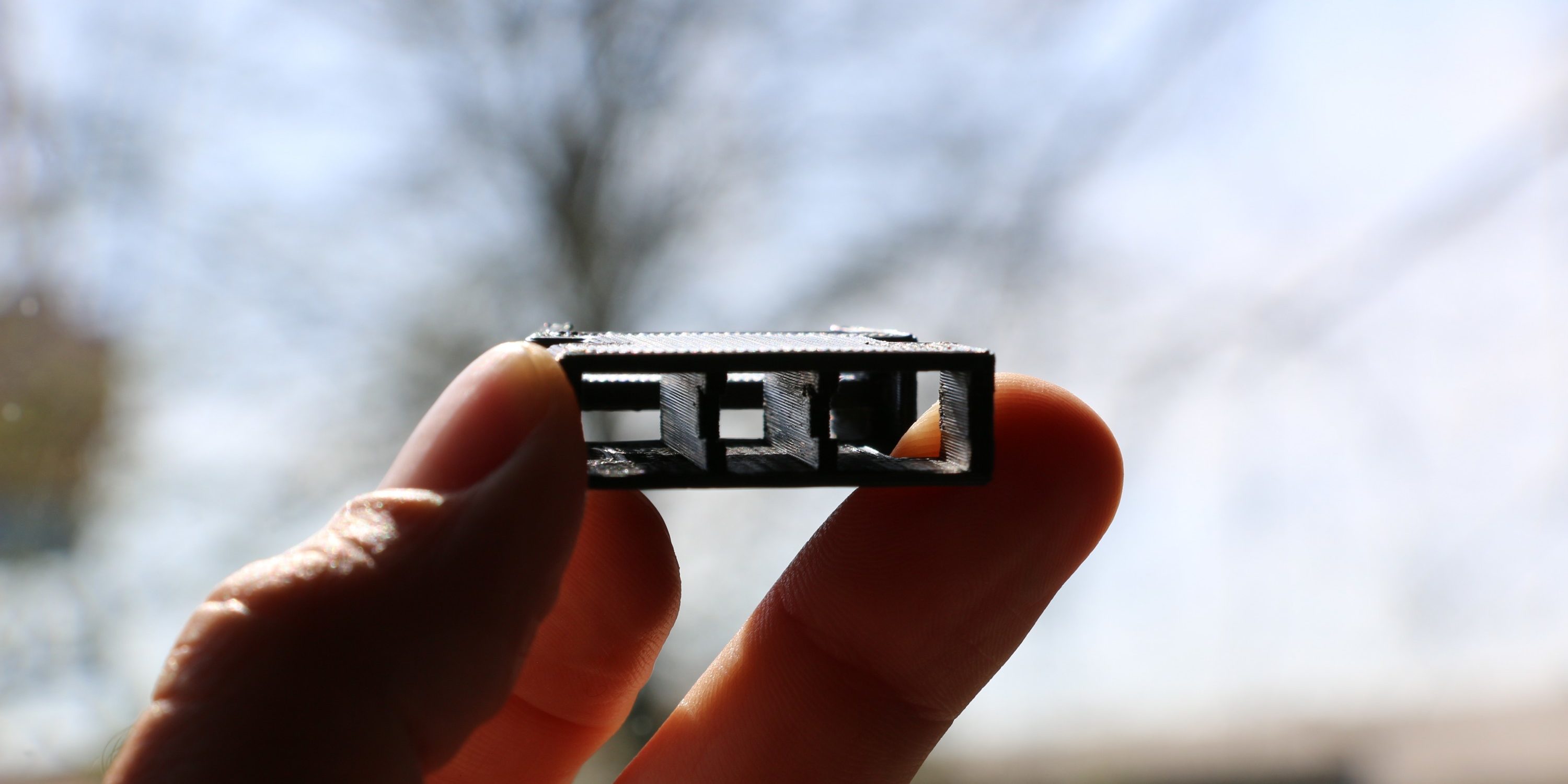

Break-away support structures made from the same material (and nozzle) like the to-be-printed object itself had to be inevitably called state of the art in this regard. So you may have already been able to print any shape to date, but may also have found yourself either unable to remove support structures without breaking the part, or ending with unsatisfying surface quality on supported bottom edges. First case caused by rather close and strong support material contact, second due to insufficient support-to-model contact in favor of simplified removal.

Issue solved!

It’s here, and it’s amazing. We are talking about true soluble and break-away hybrid support material for ABS models on Kühling&Kühling RepRap Industrial 3D Printers.

[unordered_list style=”tick”]

- Complete preconfigured toolchain

- Out-of-the-box functionality

- Incredibly improved overall process reliability (once again)

- Vastly enhanced bottom surface quality of the printed ABS parts

[/unordered_list]

See a first video demonstation below:

Powered by Slic3r 1.2.7

In the works for months now, our explicitly favoured and warmly recommended slicing engine “Slic3r” made a huge step forward since the last stable release (1.1.7). Given the incredible amount of really powerful new features like 3D plater and 3D toolpath preview (find the full release notes here), we don’t have an easy time to simply boil release 1.2.7 down to its brand new “soluble support functionality”. This is by far the most powerful feature, though, since it finally and for the first time ever within the Open Source 3D printing ecosystem enables us to truly benefit from all the infinite 3D printing freedom mentioned above.

Keep an eye on our blog to avoid missing the nifty details incorporated, as well as required hardware upgrades and software configuration for existing customers. This functionality will be backwards compatible with all of our Kühling&Kühling RepRap Industrial 3D Printer hardware revisions ever sold so far, but may require minor hardware additions. Upgrade kits will be available for sale very soon.

For the moment let’s stick to “Awesome!” and celebrate the latest developments at the upcoming

Rapid.Tech 2015 Trade Fair

June 10-11 in Erfurt/Germany

Booth 2-216

Soluble support with ABS model material will naturally be live on show there, so be sure to step by at our booth over the course of the event. Looking forward to meeting your there!

Ein Kommentar