We are excited to be able to finally publish first details on our new RepRap design after a full year of development. As we mentioned earlier we went the extra mile and started from scratch instead of modifying an existing design in order to incorporate all features we desired.

This is a true RepRap. An open source 3D printer that can print its own components by Fused Filament Fabrication from materials like ABS plastic. Nearly all additional unprinted parts are either standard parts (steppers, nuts, bolts, washers etc.), flat sheet material that is cut into rectangular pieces and drilled (acrylic and wood for the case, aluminium composite board for bottom of print bed), or extrusions and shafts that are easily cut to length with a chop saw.

For us it is very important to mention that we have incorporated a lot of good ideas from the great diversity of existing RepRaps into our design that we want to highlight as we’ll further document more details over the coming weeks.

By the way all printed parts for this prototype were printed in ABS on our very first, handcrafted RepStrap we built from scratch mid 2011. But now let us show some fotos – for a feature-list and upcoming developments see below:

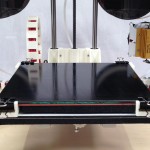

- Front view

- Front view – doors open

- Side view

- HxWxL: 80x55x55 cm

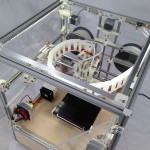

- Top view

- Doors open

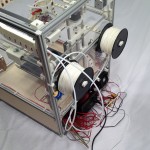

- Spool holders on the back – plus cable mania..

- Back view – cable harness waiting for new high power MOSFET driver boards to be finally wired up

- Front view

- One of four circulating air heatings – each providing 120W for 70°C chamber temperature

- Active carbon air filter

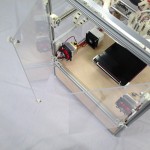

- FR4 print surface

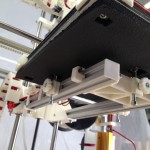

- Print bed, bottom view – semi-automatic 3 point bed leveling system

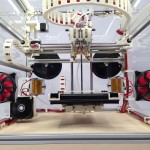

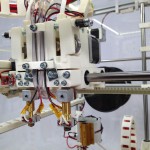

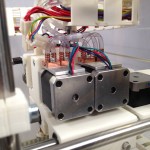

- Dual extruders, front view – water cooled hotend insulators

- Dual extruders, back view – water cooled planetary geared stepper motors

- Advanced custom cnc’d direct drive extruder gears

- Front left Y end with belt idler

- Left X end with stepper motor and hall-o endstop

- Y stepper motor

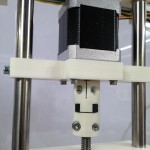

- Z stepper motor with Sugru spider coupling

Features

- Specifically aimed at printing ABS with zero warping, low maintenance effort through highly accessible sub assemblies

- Rigid frame made of 20x20mm t-slot aluminium extrusion

- Fully enclosed by acrylic and wood, doors on the front

- A heated chamber capable of 65-70°C recirculating air temperature

- Heated PCB print bed

- Water cooled hot-ends and extruder steppers to ensure reliable extrusion in high ambient air temperature

- Fully parametric design in OpenSCAD

- Dual extruders, primarily for use with different nozzle diameters for perimeters/infill to save printing time on big objects (we are testing with 0.35mm for perimeters and 0.75mm for infill at the moment)

- 3mm filament diameter

- Compact, rigid parts with integrated mounting points for endstops and such

- Activated-carbon air filter to remove unpleasant smell of molten plastic

- Cable management

- Semi-automatic print bed levelling makes calibrating the machine a matter of seconds

- Z-leadscrew bearing supported on both ends, sugru spider coupling for absolutely wobble-free operation

- 12mm precision ground shafts with LM12UU linear ball bearings on all axes (will be replaced by Igus RJMP, see below)

- Tool-free belt tensioning with built-in thumbwheels

- Direct-drive extruders with high torque geared stepper motors

- Permanent printbed material (FR4) – no Kapton or PET tape needed

- Adjustable nozzle height to align both extruders on the same level

- 200x200x200mm build volume

- Custom designed, precision extruder drive gears to provide enough grip on the filament in a heated enviroment

- Integrated LED lighting

- Hotends from reprap-fab.org with 40W each for short heat up time

Electronics

- RAMPS 1.4 controller board – we will give the R.U.M.B.A. a try as soon as it is delivered.

- Modular additional MOSFET driver boards for lights and fans

- Brand new high power 15A MOSFET driver boards (still in development by carbonfrog) for chamber heaters, total power >550W

- ATX power supply 1000W

- Water cooling based on a EHEIM/Innovatec PCPS1104 water pump

Upcoming development

- Raspberry Pi with a 10″ capacitive touch interface for ethernet enabled standalone operation

- Touch optimized user interface for the raspberry pi is in development

- The frame will be revised for 30x30mm extrusions, so we can use T-slot nuts that can be swivelled in, providing much easier assembly. These nuts are poorly available for 20x20mm extrusions

- All LM12UU linear ball bearings will be replaced by low maintenance Igus RJMP slide bearings that are rated for continuous use in 90°C ambient temperature

- Magnetic door locks

What is the actual printing volume?

You wrote 200mm^3, you mean 200mm x 200mm x 200mm, not actually 200mm3

Oh, this would be quite small indeed, thanks for the hint!

It should be 200x200x200mm of course – changed that above.

Hi Rene,

this first prototype currently has a build size of 200x200x150mm (X/Y/Z), but we aim at 200x200x200mm with the next machine by extending the vertical extrusions and acrylic respectively

Where are the files to start printing my own? I would love to make this my next project.

Hi Peter,

we are currently cleaning up the OpenSCAD source files for a first public release – those will be available through a github repository by next week, i think.

I am glad you like it!

Congrats! This printer, its construction and mechanics sound very promising and reliable. I like the heated chamber and semi-automated bed leveling. Both areas of problems today. I am looking forward to further independent test runs.

Very very nice printer.. Lots of attention to detail. Very uhmm.. German.. 🙂

A question though..

Why would you use a heated build platform when you already have a heated build area of 70degC?

Also, if you’re building your business on making money from this printer, are you not afraid that a company like Stratasys is going to come at you like a ton of bricks for infringing on their patent(s)?

Wish you all the success though! Looks great!

Hi Paul,

thanks for your feedback!

Although the build area is actively heated, we still need a heated platform to ensure proper adhesion. ABS is much less forgiving in this regard than PLA for example. The heated chamber reduces the thermal stress a lot, but does not eliminate it entirely (but raising the temperature even higher is impossible due to the self-replicated-from-ABS nature of the RepRap construction 😉 )

Regarding the subject of patents: That’s right. This is a common concern with every new product and particularly tough for start-ups.. We are currently evaluating that topic to make sure we don’t accidently tread on someones shoes. But we are quite confident to find solutions if problems should arise.

check out slashdot yesterday http://yro.slashdot.org/story/13/02/20/0317250/the-patents-that-threaten-3-d-printing … and this article on patents: http://www.wired.com/design/2013/02/3-d-printing-patents/?pid=1994&viewall=true

Seems a “heated enclosure to prevent warping” may be patented (groan…)

Unless you are planning on selling these printers, at least in the US a Patent does not apply to anything home built for personal use. There is no limit on the number of these a person may build as long as the do not offer them for sale.

Also I am pretty sure you could sell a kit of parts and just leave out the panels for the enclosure. It is simple, cheap and easy to have some plexiglass cut locally which should overcome any other obstacles.

Very nice design, congratulations.

I’m curious to see the results of the ABS printed in oven.

Perhaps some details about layer thickness and speed?

Best wishes for your project guys!

Hi Virgo,

keep an eye on this blog, we’ll publish more details on this in the coming days..

Simon, great job. Besides it’s functional use it looks beautiful too!

(Also, If you’re interested in putting it up on 3dhacker.com please register any time and we just need to remove the Anti-Spam Verification on your username. We’d love to add it to the small but growing list of printers from around the world!)

Andrew

http://www.3dhacker.com

How much did all of this +/- cost? 🙂

Well, you don’t really want to know 😉

We spend quite a LOT into the first prototype – due to part evaluations, low quantities of special parts etc…

The Bill of Material is being completed at the moment – and last touches are made to a first release of source files. So stay tuned for the final bill 🙂

Will/is it GPL-licenced? 🙂

Hi Daniel,

the sources will be published under the Creative Commons Attribution-ShareAlike license (CC BY-SA 3.0), which in our opinion is better suited for open hardware projects that include more than just written source code.

Expect them to be released the coming days – you’ll find an announcement here on our blog, of course!

Simon,

are the openscad files already available ?

Love this printer, great work….

Michael,

we have just set up a github repository at https://github.com/kuehlingkuehling/RepRap-Industrial-200

Current version is 1.0-dev, which is the development version until we finalize version 1.0 for production.