After the typical time of pre-production, in which there is naturally little to report about outward visible successes and progress, we are back with an update on our RepRap Industrial 3D printer.

Over the last few weeks we certainly must have experienced 90% of what is said to be the inevitable challenges a startup has to overcome in the process to move from prototype to series manufacturing. That includes non-delivery of supplies and the literal quest for substitute manufacturers.

We are now located on a shipyard site at the Kiel Fjord, in the middle of drydocks, cranes and yelling seagulls.

Meanwhile we moved to a larger production facility with plenty of spare space to further grow and expand our own capacities.

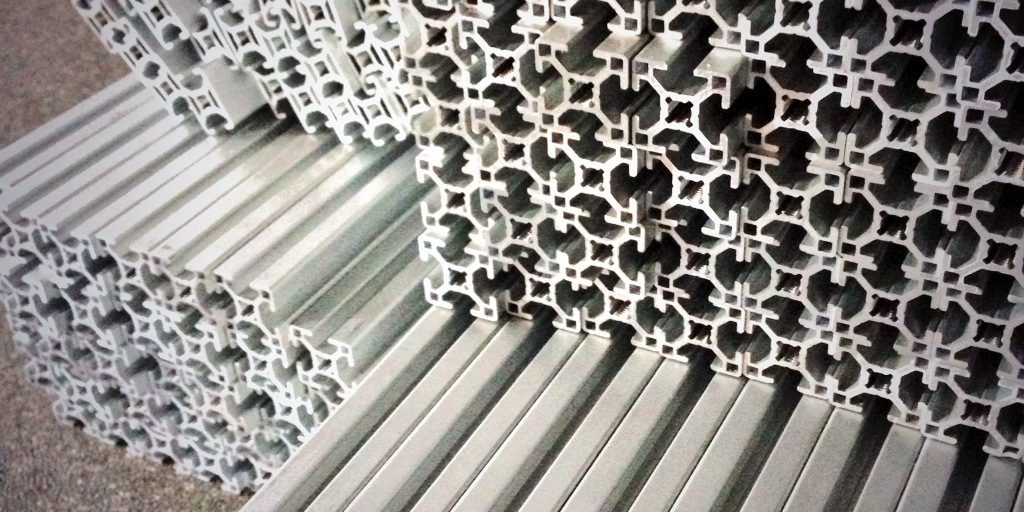

Gladly we managed to overcome all obstacles to date without too much delay, which confirms our initial schedule – which we have set up with ample reserves in wise expectation. Now we can proudly announce that we already started assembling first production units.

Wait – assembling? You’re right! Over the past weeks we’ve been busy speeding up the preparations necessary for shipping fully assembled, tested and ready-to-use 3D printers with CE label as it is required by european regulation. The CE label mainly states conformity with health and safety regulations valid in the European Union. While this may or may not be required for all the countries we are shipping to, it still ensures that our product meets highest quality and safety standards.

In the process of finalizing the design for production, we could not resist to facelift the whole machine from top to bottom and adding an extra 20% build volume along the way. Just a minute ago the online-shop got updated to the latest specifications – take a look!

In the process of finalizing the design for production, we could not resist to facelift the whole machine from top to bottom and adding an extra 20% build volume along the way. Just a minute ago the online-shop got updated to the latest specifications – take a look!

There are little expectations to take this turn of the years as contemplative as we were used to – we will likely be passing it at full throttle instead. But first there is still one highlight left for 2013: We will exhibit at EuroMold trade-show in Frankfurt next week – read the details in the next post in a minute.